Understanding the Importance of Running at Rate

Luminar’s successful completion of this particular R@R audit marks a critical achievement in advance of SOP, and the precursor to the launch of the Volvo EX90 featuring Luminar LiDAR as standard on every vehicle.

Last Friday, Luminar announced that we recently passed a critical “Run at Rate” audit process, or R@R, for Volvo Cars in our high volume facility in Mexico. Successful completion of R@R is required by all automakers in order to demonstrate start of production (SOP) readiness. Luminar’s successful completion of this particular R@R audit marks a critical achievement in advance of SOP, and the precursor to the launch of the Volvo EX90 featuring Luminar as standard on every vehicle.

What is a “Run at Rate” audit process?

R@R is a critical quality control procedure in the automotive industry that ensures a successful transition from the pre-production and low volume production phase to high volume series production. During R@R, each step of the manufacturing process is tested and key performance indicators such as cycle time, yield, and production output are precisely measured. Any discrepancies or issues that arise during R@R are rigorously addressed to ensure that the production line can consistently meet the specified production targets from the automaker customer, while also meeting the necessary quality and yield standards. R@R is usually performed by the supplier under the on-site supervision of the customer.

Why is it important for Luminar?

Our successful R@R effectively ensures that our Mexico facility is able to produce at the initial production rates and quality metrics Volvo Cars requires of us once they reach SOP. We performed this R@R together with our contract manufacturing partner, Celestica, under the on-site supervision of Volvo Cars.

This collaborative approach helps optimize the manufacturing process and ensures that all parties involved are well-prepared for the start of high volume production, ultimately enhancing product quality, minimizing production defects and downtime, and ensuring the timely delivery of quality LiDARs to Volvo Cars’ assembly plants. The successful passing of R@R means that we have effectively proven we can produce at the required initial production rates and quality standards for Volvo Cars’ upcoming EX90 SOP.

What work did we do to pass R@R?

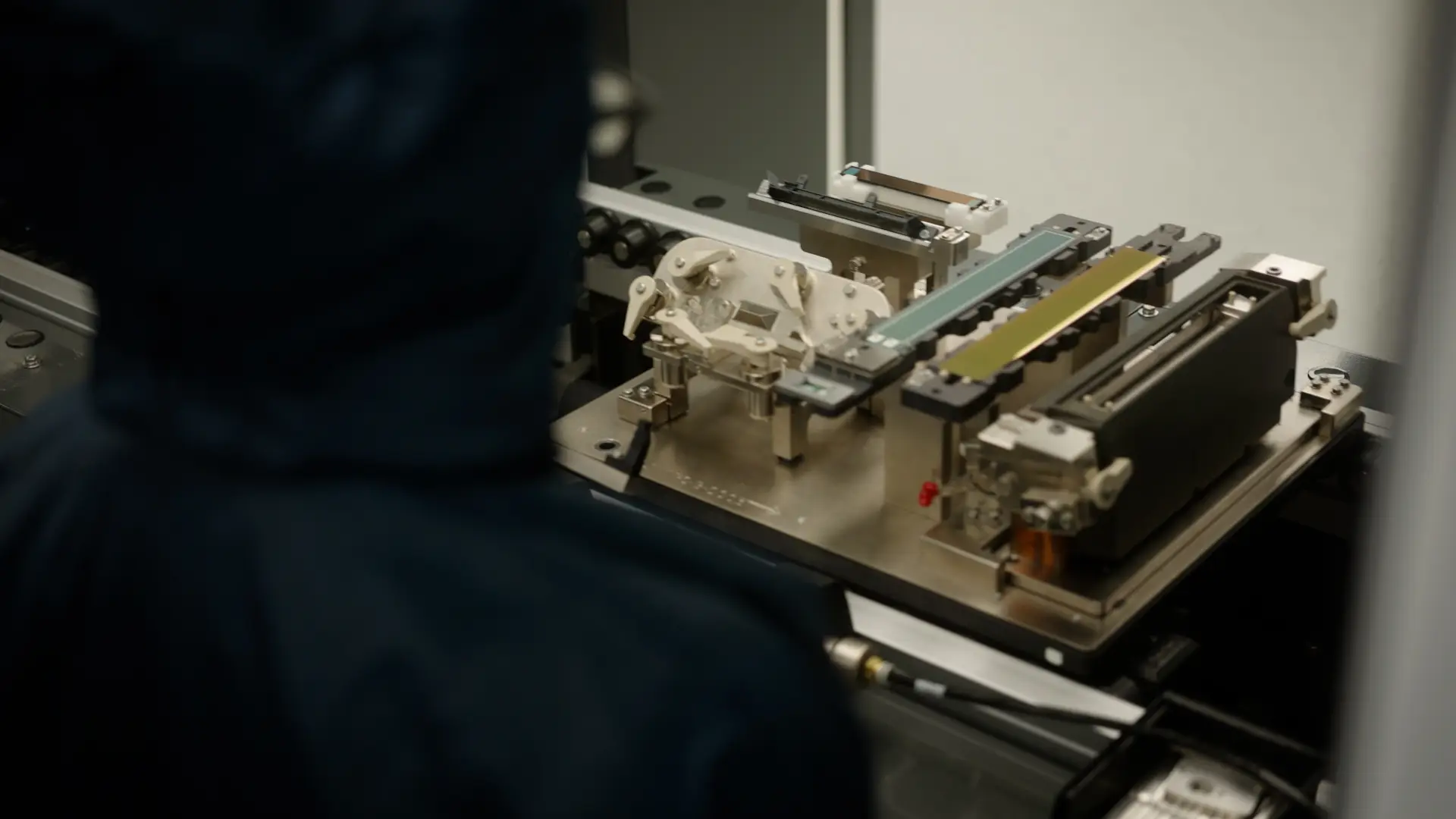

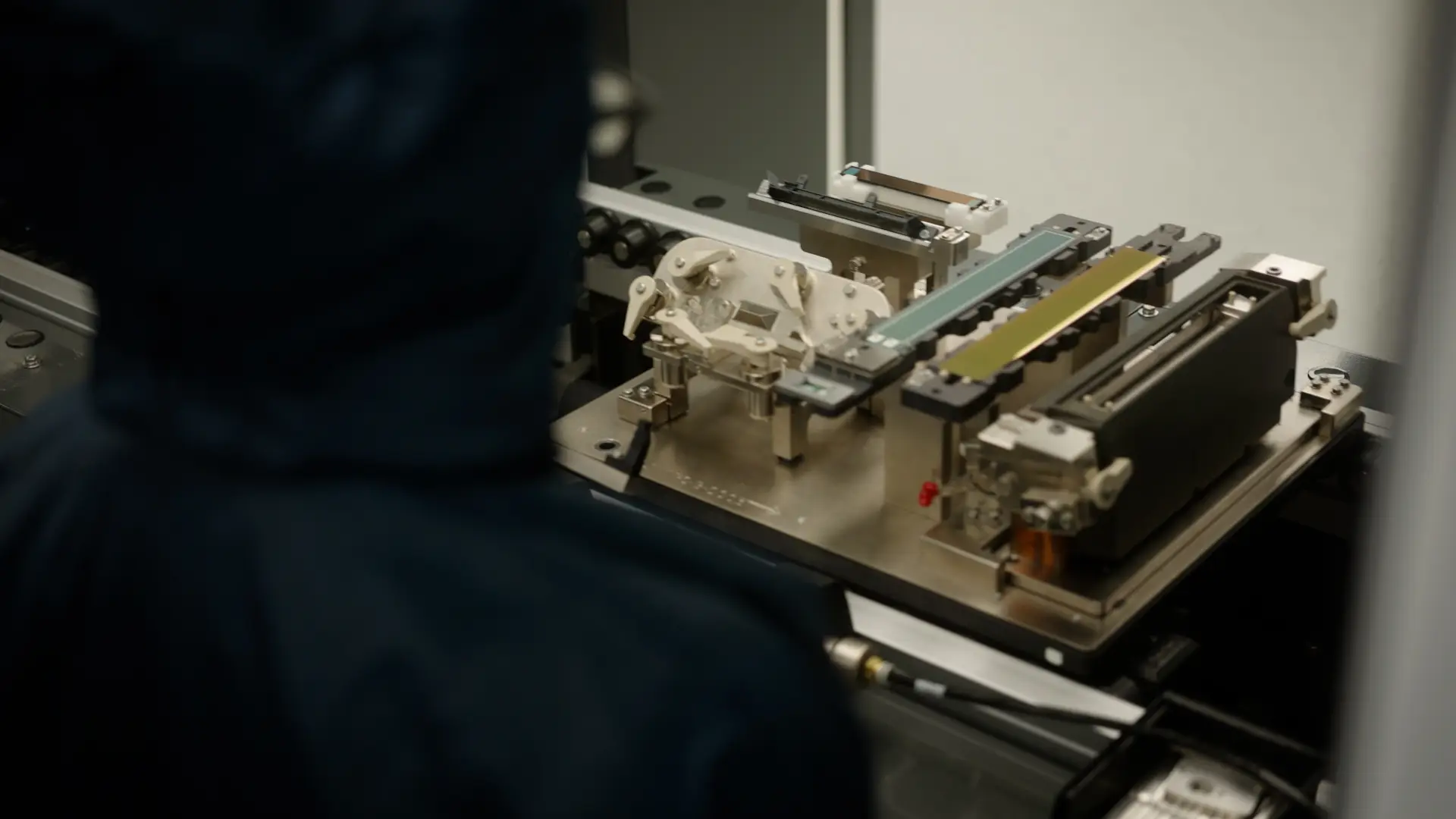

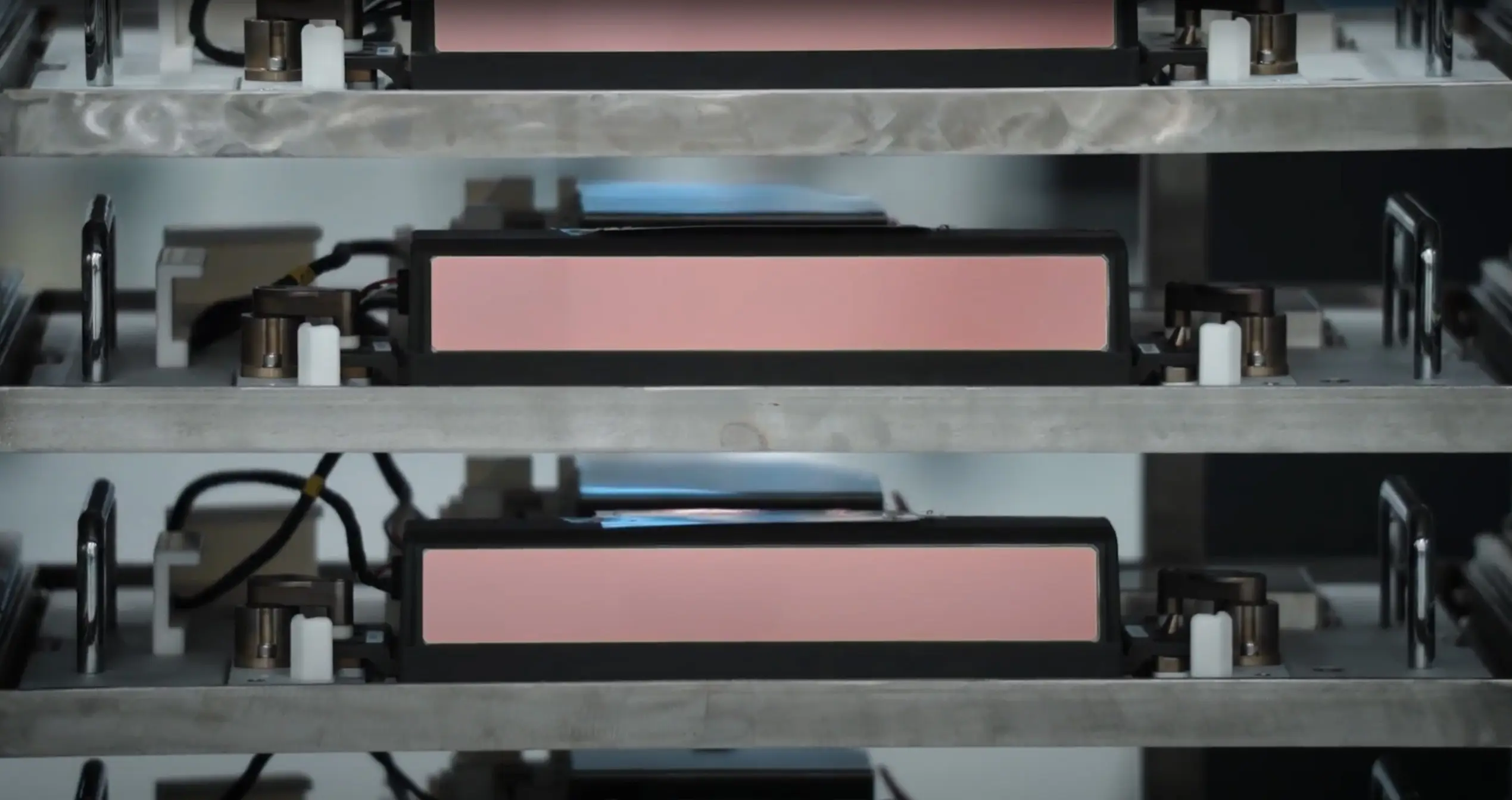

The specific work by the Luminar team to meet this critical production milestone began nearly 18 months ago with the site selection of our new dedicated facility in Monterrey, Mexico and ordering of our high volume, highly automated production line. We spent nearly 12 months and over $50 million to complete the construction of our dedicated Mexico facility, including the installation, testing, and debugging of the final assembly and testing procedures for our highly automated line.

In March of this year, we started producing our LiDAR sensors in low volumes at our Mexico facility to assess the automation line, yield, and quality of sensors produced in order to work out any ‘manufacturing kinks’. We continued producing our LiDAR sensors through the summer at increasingly higher rates and assessed the automation line, yield, and quality after each trial run, and began the formal R@R in late September. With Volvo Cars personnel onsite to supervise the audit, we produced our LiDAR at the required production rates and necessary quality standards for the EX90 SOP, successfully passing the R@R.

So what remains before the official Volvo EX90 SOP? We believe a lot of the heavy lifting has now been completed and we are shifting our primary focus to now optimizing our production processes and unit economic costs, including both our bill of material (BOM) and manufacturing conversion costs, as well as ensuring our entire supply chain can ramp up with us in similar quantity and quality. We will perform future R@R audits not only for Volvo Cars, but for other automakers, as our existing and new customers ask us to manufacture at increasingly higher production rates.

Passing this recent R@R was a critical achievement and often one of the most difficult production milestones. We have learned a lot over the past 18 months preparing for this audit and will apply these lessons to ensure we can increase our production rates more efficiently and quickly in the future as we continue to grow.

Thanks to our customer Volvo Cars and to all of you for your continued support as we work towards enabling the world’s safest and smartest vehicles.

Sincerely,

Kevin and the Luminar team